311RS Dyno: 991 GT2RS & GT3RS

We dyno two of Porsche’s latest 911s in order to establish a baseline for each project. Read on to see how these two beasts fared on our local Mustang dyno.

The first step in any project we work with here at 311RS is to record baseline numbers – i.e. weight, lap times, power, etc.

With RS Motors 30 miles away, we have local access to a Mustang Dyno. We prefer a Mustang dyno for it’s load-based calculations – simulating the rolling resistance a car will see in the real world.

Numbers may not be as high as an intertia-based Dynojet, however the numbers provided from a Mustang dyno are reliable and consistent across the industry.

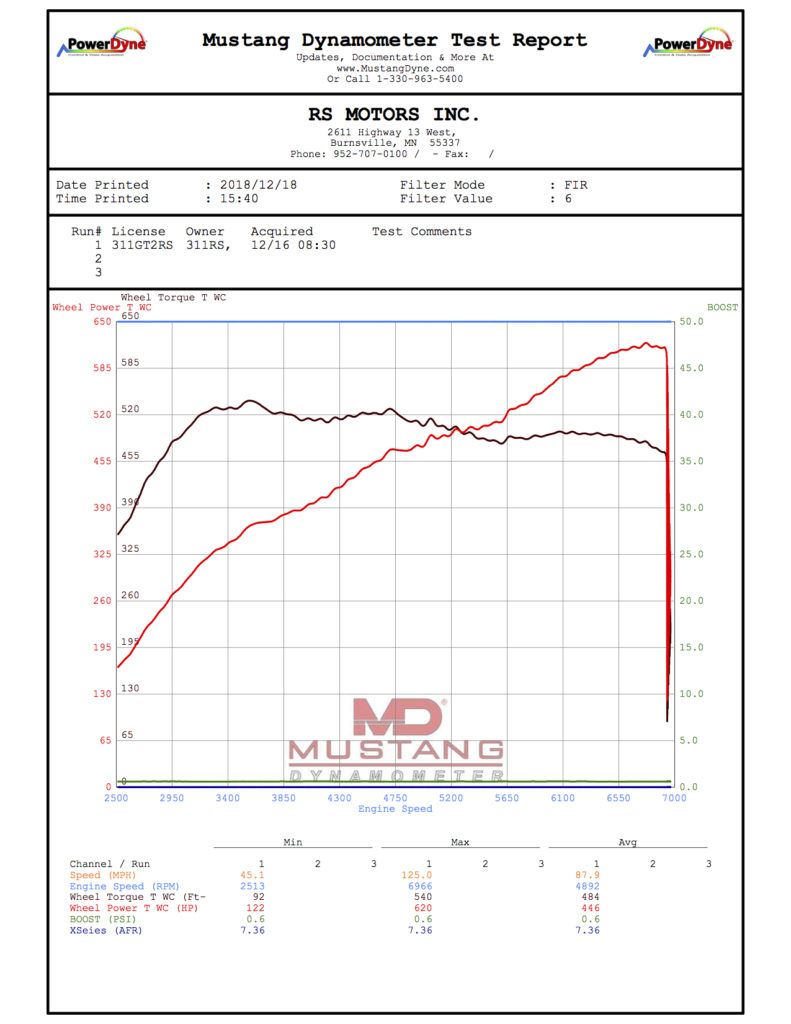

First up, the 2018 GT2RS is loaded onto the rollers for it’s baseline runs. The car is sufficiently broken in with 1,130miles on the clock. Porsche quotes the car at 700hp at the crank from the factory.

We ran the GT2RS for three pulls on the Mustang dyno. Seeing a car run under load on a dyno never gets old!

The GT2RS produced a healthy 630whp and 547tq on it’s final run. These numbers confirm this unit is making at least the 700hp quoted from Porsche.

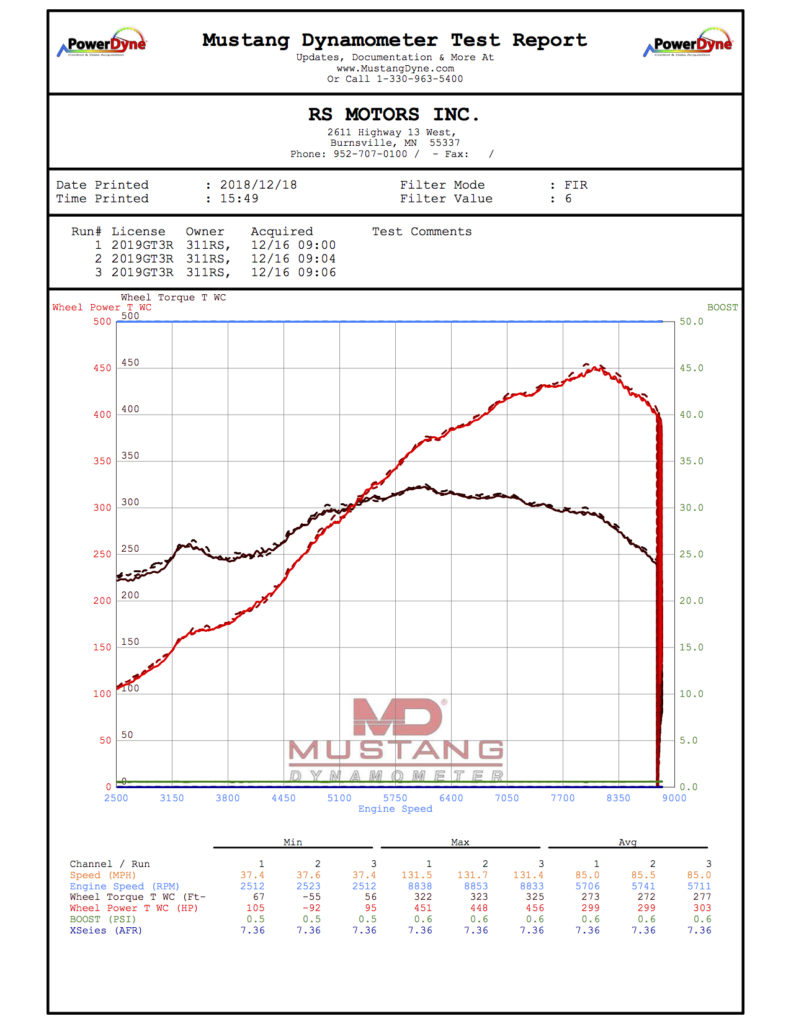

Next up we have a 2019 GT3RS with 500 miles on the clock. No doubt still a bit tight, however there is no time like the present for a baseline dyno given our plans for the car this winter.

The 4.0L N/A engine in the 991.2 GT3RS is rated at 520hp at the crank from the factory.

Again, this car appears to be quite healthy – producing 456whp & 325tq.

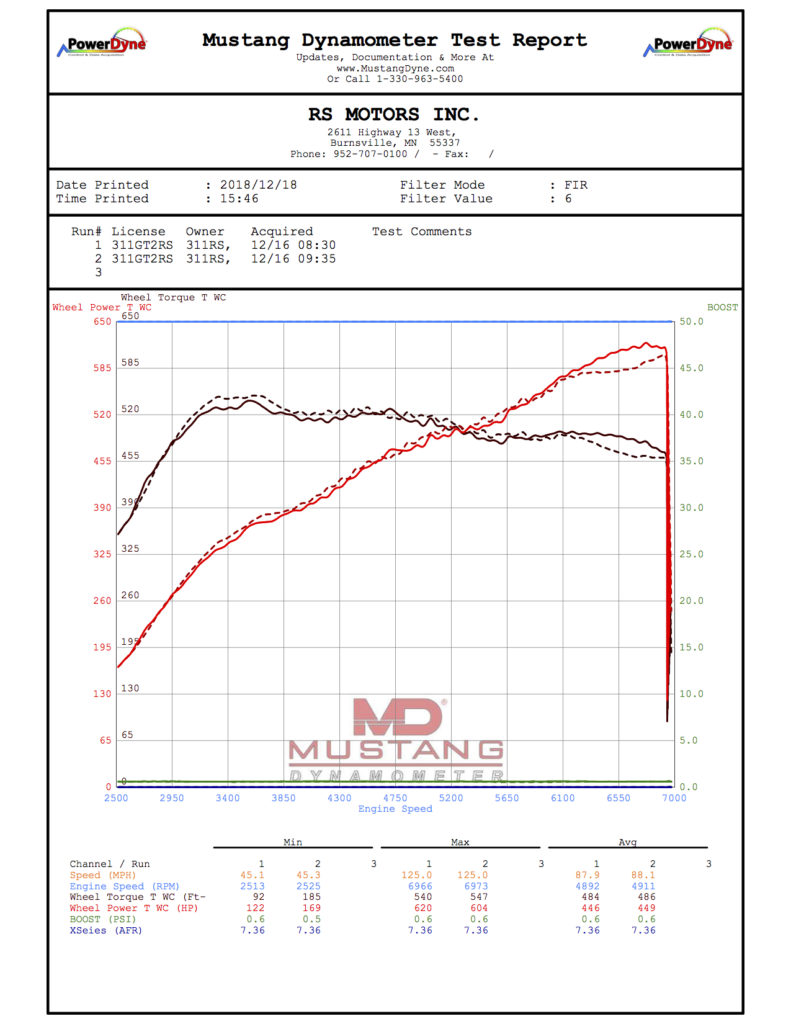

While the GT3RS was making it’s runs, Ryan worked quickly to swap the exhaust on the GT2RS – removing the OEM catted & valved system and replacing it with our prototype 993 GT2 Evo-inspired straight pipes made locally here in MN by the guys at Patience Metal Fab.

The goal with these pipes is two fold – remove weight and reduce restriction.

Onto the dyno the car went. At this point, the car is running the factory tune and is not optimized for the additional flow of our straight pipes. Even so, it is important we see how the car responds with an exhaust swap alone.

Porsche runs a heavily torque-based control strategy with it’s ECU. Just because there is a reduced back pressure doesn’t mean the car will produce more power than the target torque value. The ECU will close the throttle, limit wastegate duty cycle, etc. to keep that targeted number exactly the same.

A look at the back -to-back dyno plots between stock exhaust & straight pipes confirms the above. The ECU clearly does not like the additional flow and as the revs increase it consistently trims power off the top end.

All of this leads to one thing – tuning. We cannot wait to unlock the potential of these cars by dyno tuning them. Mitch from COBB will be paying us a visit come mid-January to tune each of these cars with COBB AccessPorts.

By the time Mitch arrives in MN, the GT3RS will have a Dundon Motorsports longtube header system on it. Those alone are said to make good power without a tune, so we’ll confirm that and move forward with tuning after a few baseline runs.

As for the GT2RS, we’ll have the car tuned for the OEM exhaust as well as the straight pipes. In the event we visit a track with noise restrictions, it’s important we can still run the OEM system to good effect.

Our next area of focus will be on the aero department. The parachute caused by removing the rear muffler is to be addressed, as is additional cooling to ensure we aren’t burning up the back of the car with these 5″ straight pipes.

Until then, please enjoy this video of the GT2RS putting launch control to the test on slippery December roads here in MN. Turn the volume up!!

GT2RS owners interested in the development of our GT2RS program, please contact us and we’ll keep you up to date with each step of the process.

Photos courtesy of Peter Lapinski.